how does vapor honing work

It is the ideal for all types of materials metallic and non-metallic. Vapor Honing is the same process as wet blasting and vapour blasting.

Slurry Pumping System S Vapor Honing Technologies Youtube

These kinematics give this process the typical honing angle.

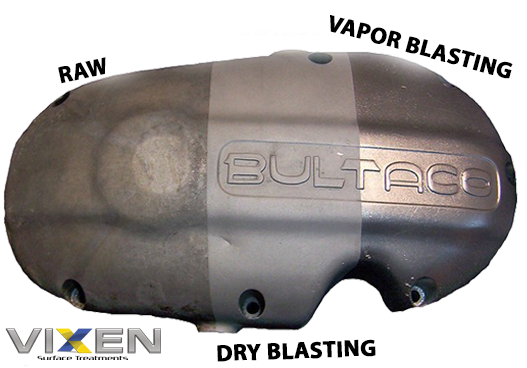

. No media is impregnated into the component nor is there any dust created by the break-up of media unlike dry blasting where the finish is produced by sheer force of media impact. Wet blasting vapor blasting is a process for removing contaminants from a surface or finishing a surface using pressurized water and abrasive blast mediaIf the abrasive media is mixed with water and pressurized in a pressure pot before being propelled through a blast nozzle and mixed with compressed air. It leaves a smooth satin finish and is much more gentle to the surface than dry sand or glass bead blasting.

Perfect for use on new components or refurbishment of any type of machinery. Vapor honing also referred to as vapor blasting or wet blasting is a surface refinishing process used to clean and restore surfaces. Cuda parts washer using Cuda SMP-1000 Soft Metal Powder Detergent and Cuda Vapor Corrosion Inhibitor.

Consequently how does Vapour blasting work. If youre cleaning a surface then the vapor honing machine works on several levels. Vapor honing is a finishing process that utilizes water and various types of fine media to restore parts to OEM finish.

The first of many advantages of wet blasting is it cleans by flow of water and abrasive running across the part surface not by sheer force and impact like in conventional dry blasting operations. This Slurry will flow across the surface polishing or breaking up whatever you are trying to remove. Vapor honing uses water and abrasive flowing across the surface to scrub away contaminates rather than directly impacting the surface damaging and removing material.

The feed movement causes a radial spreading of the tool whereby the abrasive makes contact with the bore walls. Its perfect for restoration work because it makes the metal surface look like new but does not remove metal like sandblasting. Vapor honing is a wet blasting process which uses very fine glass beads and water under air pressure.

First it will clean the surface of any materials and any grease. Instead of dry abrasive media used in sandblasting it uses a combination of water compressed air detergents with finer and gentler media to remove oxidized metal and corrosion. The process has numerous functions for example-.

Using vapor honing will speed up the cleaning process make less of a mess than dry blasting and do a better job of scrubbing off any chemicals dirt or debris. Using a fine glass bead slurry mix with 25-60 psi 37 cfm this is a high volume low pressure process that gets down into the fine areas removing any dirt grime rust or corrosion without removing any metal. Advantages of Vapor Honing.

The key to vapor blasting is that the finish is produced through the flow of water borne abrasive giving a finer finish due to the flushing action of the water. With water serving as lubricant the pressurized slurry mixture wont scar heat or warp the original surface of the part allowing even delicate internal engine components to be vapor honed. The equipment then blasts these abrasive particles onto the surface with compressed air.

The vapor blasting process. Now that you know about vapor honing and the benefits that make it a better solution for parts cleaning you might want to check your equipment to see if it needs a rinse. The abrasive nature of the cleaning means the part is scrubbed clean by default.

A Simple Introduction To Vapor Honing Issuu Vapor Blasting What It Is Costs And Shipping Cleaning Pistons Using Vapor Blasting Vapor Honing Technologies Youtube. It is executed by the tool and includes the lifting turning and feed motion. An essential feature of the honing process is the process of kinematics.

Vapor blasting also known as wet blasting liquid honing or dustless blasting is a process that uses pressurized water and abrasive material to remove contaminants corrosion residue or coatings from a surface. To remove imperfections such as heat treat scaling you add fine abrasives to the water then sprayed onto the material at great speed. Then it will clean the surface itself with the water of the abrasive materials that have been used in the process.

Vapor Honing An Engine The Ultimate Guide

Vapor Hone Up And Running Bike Builds Motocross Forums Message Boards Vital Mx

Slurry Blasting Vapor Blasting Equipment For Sale Vapor Honing Technologies

Vapor Honing Bonehead Performance

What Exactly Is Vapor Honing 5 Things You Should Know

Cleaning Pistons Using Vapor Blasting Vapor Honing Technologies Youtube

Vapor Honing Blasting Superfly Garage

Vapor Hone 1000 Wet Blasting Equipment Blast Wash Systems

A Simple Introduction To Vapor Honing Issuu

Vapor Honing Services What Is Vapor Honing And Does It Work

Vapor Honing Services What Is Vapor Honing And Does It Work

Vapor Blasting Cast Iron Using Crushed Glass Vapor Honing Technologies Youtube

Vapor Blasting Services Wet Blasting Vapor Honing Technologies

Before After Vapour Blasting Automotive Restoration Repair Vapor